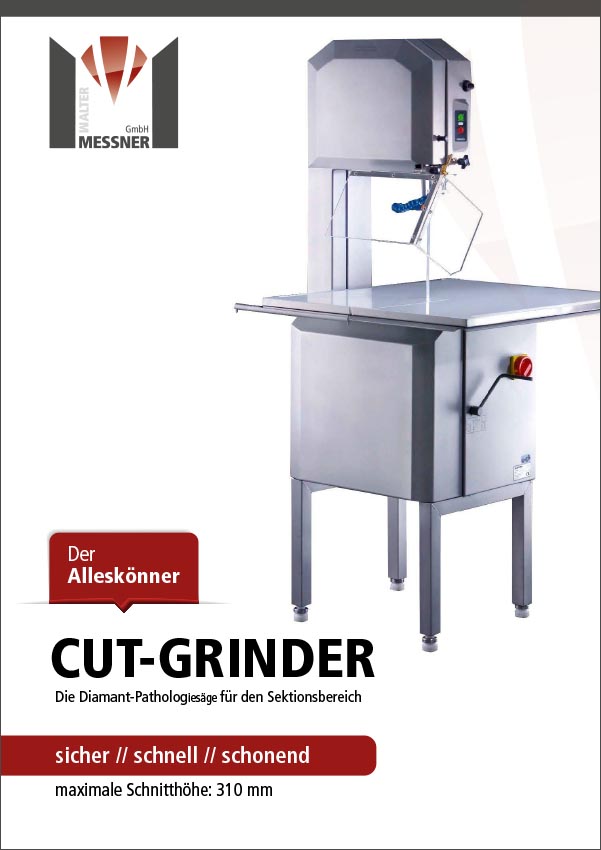

cut-grinder: The diamond pathology saw

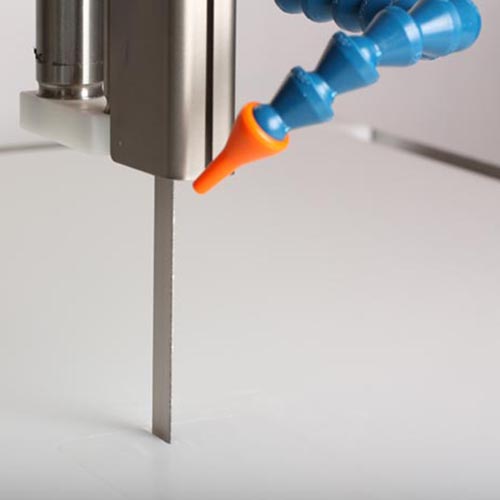

The cut-grinder is our large diamond cutting unit for cutting bone, tissue and implants. A great feature of our saws is your safety during the cutting process, as the cutting band of the cut-grinder has a galvanic diamond coating. The cutting process is therefore a grinding process. This not only minimises your risk of injury, you also get an excellent result when cutting – without burrs, burns and chipping. The bandsaw blade therefore also allows for the smallest sample sizes – the decalcification times are greatly reduced.

The stepless speed control ensures optimal running smoothness and slow cutting of sensitive preparations. You can use the cut-grinder for native samples as well as preparations embedded in plastic. Normal tap water is used to cool and rinse the bandsaw blade at the same time.

The cut-grinder is regularly inspected by the professional association for safety and hygiene.

Equipment cut-grinder

- Motor protection with restart interlock

- Motor brake

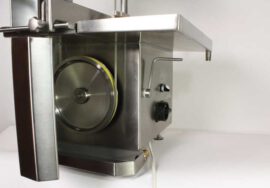

- Impellers completely made of stainless steel

- Upper impeller can be completely removed

- Bandsaw blade is tensioned by a gas spring

- No adjustment errors possible

- Membrane keyboard

Technical data cut-grinder

| Power | Three-phase alternating current |

| Voltage | 400 V |

| Frequency | 50 Hz |

| Blade speed | Steplessly adjustable |

| Power consumption | 2,0 KW |

| Wheel diameter | 315 mm |

| Weight | 110 kg |

| Installation area (WxD) | 500x440mm |

| Outer dimensions (WxDxH) | 777 x 810 x 1600 mm |

| Ground clearance | 400mm |

| Cutting height | 330mm |

Bandsaw blades

- 0,3 mm D 151 // art. no. 503462 – recommended for normal cutting (bone/tissue/ femoral head) our “bestseller”.

- 0,3 mm D126 // art. no. 503461 – recommended for cutting rubber profiles (automotive industry) and finer cuts in medicine (bone/tissue/ femoral head)

- 0,4 mm D181 (coarse grain) segmented // art. no. 503466 – recommended for long cutting surfaces (e.g. femur)

- 0,2 mm D 64 // art. no. 503445 – recommended for finer cuts, e.g. teeth and cut-thin technique

- 0,1 mm D64 // art. no. 503444 – recommended for very fine cuts in the separating thin section technique (very small implants from the field of cardiology)

Which device is the right one for me?

| cut-grinder | primus 2 | |

| Design | Free-standing unit | Table-top unit |

| Cutting height | 310mm | 220mm |

| Specialist for… | Femur, larger implants | femoral head, jaw segment, smaller implants |

| Bandsaw blade thicknesses | 0,1-0,4mm | 0,1-0,3mm |

| Engine | 2 KW | 600 W |

| DGUV mark | yes | yes |

| Adjustable speed | yes | yes |

| Bandsaw blade tension regulated via gas pressure spring | yes | yes |

| Water supply | directly | Possible directly or via water tank |

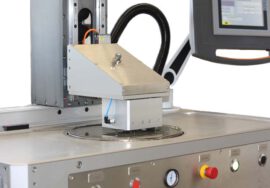

| Upgrade with parallel guide possible | yes | yes |

| Weight | 110kg | 60kg |

Quality control with the cut-grinder

Our cutting systems are not only used in medicine. Especially in the automotive industry, the cut-grinder is indispensable for cutting profiles with or without metal inserts.

For cut-grinding, we recommend using it without adding water to prevent lubricating films. You achieve exact cuts with excellent surface quality. The prerequisite for quick evaluation or further processing.

For the processing of rubber profiles we recommend the following bandsaw blade:

- 0,3 mm D126 // art. no. 503461 – Diamond bandsaw blade

Recommended equipment:

- Guide rail for plane-parallel cuts // 500009 – diamond bandsaw blade