Quality assurance

cut-grinder: The diamond pathology saw

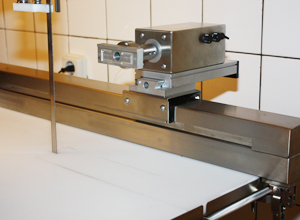

The cut-grinder is the globally unique diamond pathology saw with a cut height of up to 330mm! This static cutting and grinding system with fixed work table has been developed for the preparation of tissue, bone and composite materials such as metal and/or ceramic materials. It takes into account the requirements and wishes of leading pathologists and can also be used for thin-section cut-grinding applications.

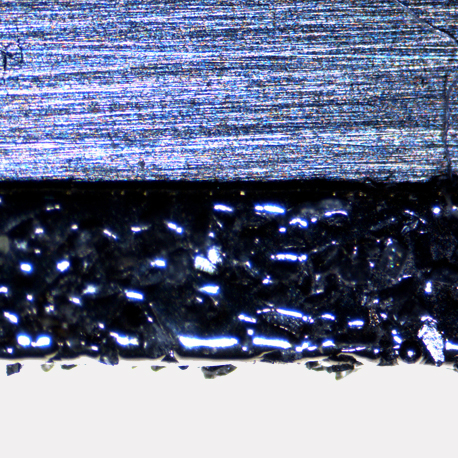

For cut-grinding, a high-precision diamond-coated cutting band is used. This produces precise sections with exceptional surface quality: The prerequisite for rapid, histological evaluation or further processing.

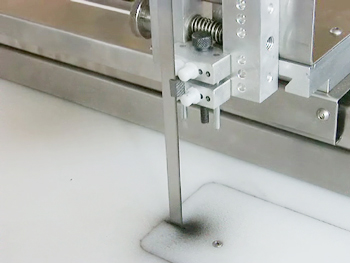

The diamond cutting band is simply and conveniently tensioned, relieved or removed by means of a lever. Because fastening takes place on the basis of defined values and this is therefore not down to the subjective feeling of the user, overheating, chipping and micro-fractures in the specimen are excluded:

Numerous additional details also make your work significantly easier. The table equipped with a detachable trough, the large work surface, a cutting height of up to 330mm and the stable and adjustable spray guard, which facilitates a complete view of the cutting area.

Additionally, work with the cut-grinder is extremely safe: The non-toothed and slow-running diamond cutting band significantly reduces the risk of injury and infection that exists with conventional band saws. This is also the opinion of the employers' liability insurance association, which has tested and approved the cut-grinder.

The cutting band is constantly sprayed and cooled with fresh water; closed circuit cooling and a trough are not included for reasons of hygiene. The device is produced entirely from stainless steel and is maintenance-free. It can be cleaned with ease, because all external parts are smooth-surfaced and highly accessible. Furthermore, there are no painted surfaces or attachment parts anywhere on the device.

cut-grinder technical data

- Motor protection with restart block

- Motor brake

- Running wheels fully stainless steel, top running wheel can simply be removed

- Saw band quick tensioning - no adjustment errors possible

- On/off switch with membrane keypad

technical data cut-grinder

| Current | Three-phase A/C current |

|---|---|

| Voltage | 230/400 V |

| Frequency | 50 Hz |

| Band speed | Steplessly variable |

| Nominal current draw | 3.6 A |

| Power consumption | 2.0 KW |

| Work table | 800x800 mm |

| Wheel diameter | 315 mm |

| Weight | 110 kg |

| Installation space (WxD) | 500x440 mm |

| External dimensions (WxD) | 777x810x1600 mm |

| Cutting height | max. 330 mm |

Accessories

- Cutting band 0.3 mm D 151

- Cutting band 0.3mm D 126

- Cutting band 0.2 mm D 64

- Cutting band 0.1 mm D 64

- Cutting band 0.4 mm D 181

- Cutting band 0.4 mm D 181 segmented

- Yellow running belt

- Plastic support plate

- Spray guard

- Top cutting band guide, plastic

- Bottom cutting band guide, plastic

- Care solution

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"

What can we do for you?

You wish to find out more about our first-class products?

Simply get in touch with us: We look forward to hearing from you and will be happy to advise you!

Telephone +49 40 714873-0

cut-grinder:

The CP "Contact Point" cut-grinder system

The cut-grinder can be modified into the "Contact Point" cut-grinder system with just a few actions. This merely requires a guide sled, available to order separately: This is fastened on the work table of the cut-grinder with the aid of a quick-release system. As with the cut-grinder, users profit here from the ease of use and the rapid cleaning.

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"

Quality assurance

cut-grinder primus: The compact diamond pathology saw

The cut-grinder primus operates on the same principle as our cut-grinder and has been specially developed for applications in small pathology departments and labs. Due to its compact design it can be installed and used within the installation space. However, its cutting height is still a max. 210 mm. The new type of work surface with the cut-grinder primus, a further development of the cut-grinder charly, enables optimum water drainage and ensures additional cleanliness in this way.

The cutting band is constantly sprayed and cooled with fresh water. Thanks to a water tank, the water supply is also guaranteed without a direct water connection. As with the cut-grinder, the cut-grinder primus also has an adjustable spray guard. The user is protected against the spray water, whilst also maintaining a clear view of the work area.

Also with this compact cut-grinder version, the tensioning, relieving and releasing of the diamond cutting band takes place with a gas pressure spring on the basis of the pre-set, optimum tensioning values.

The table of the cut-grinder primus is equipped with a detachable trough. Its large working area and cutting height of 210 mm enable a perfect working process. And cleaning is simple: On the one hand because the device is produced entirely from stainless steel and is maintenance free. And also because all of the external parts are smooth-surfaced and highly accessible - furthermore, the device has no painted surfaces or attachment parts.

When it comes to industrial safety the cut-grinder primus is also equal to its bigger brother: The non-toothed and slow-running diamond cutting band significantly reduces the risk of injury and infection that exists with conventional band saws. The cut-grinder primus has been tested for safety and hygiene and approved by the employers' liability insurance association.

cut-grinder primus equipment

- Motor protection with restart block

- Motor brake

- Running wheels fully stainless steel, top running wheel can simply be removed

- Saw band quick tensioning - no adjustment errors possible

- On/off switch with membrane keypad

technical data

cut-grinder primus

| Voltage | 230 V |

|---|---|

| Frequency | 50 Hz |

| Band speed | Steplessly variable |

| Wheel diameter | 220 mm |

| Weight | 50 kg |

| Installation space (WxD) | 500 x 440 mm |

| External dimensions (WxD) | 500 x 590 x 915mm |

| Cutting height | max. 210 mm |

Accessories

- Cutting band 0.3 mm D 151

- Cutting band 0.3 mm D 126

- Cutting band 0.2 mm D 64

- Cutting band 0.1 mm D 64

- Yellow running belt

- Stainless steel support plate

- Spray guard

- Top cutting band guide, plastic

- Bottom cutting band guide, plastic

- Care solution

- Stainless steel care product

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"

Quality assurance

Diamond cutting bands

We produce diamond cutting bands for all conventional machine types in a wide range of dimensions and with various grain sizes. Ultra-modern electroplating and the latest laser technologies, which we use for welding and cutting, ensure the maximum quality of our products.

We supply our cutting bands as standard in rust-proof stainless steel, although in other types of steel on request. You can obtain detailed information on our range of stock from us directly: We look forward to your inquiry.

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"

Quality assurance

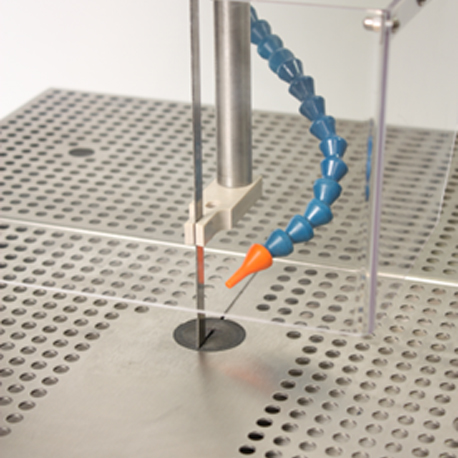

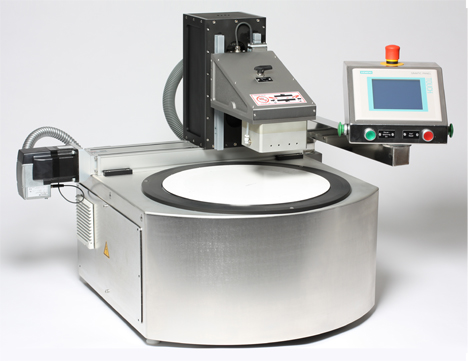

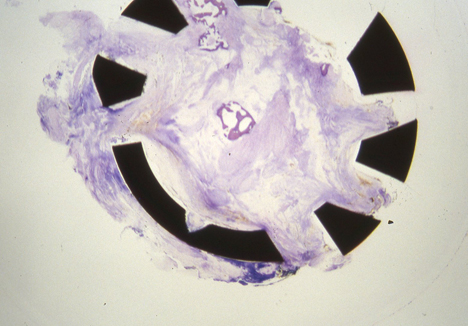

lap-grinder: Thin-section grinding system

The lap-grinder, a thin-section grinding system, has been specially developed for thin-section cut-grinding according to the design principle of Prof.Dr.Dr.h.c.mult. Karl Donath. Using this system, histological thin-section cutting is possible to approx. 10 µm. The decisive advantage of the lap-grinder in comparison to other thin-section devices is its high degree of accuracy.

All settings can be entered with ease via a touch panel. Storage space for 20 program allows you to conveniently call up settings such as weight, speed etc. after entering these just once.

The integrated water controller minimises water consumption and reduces the risk of water damage in the lab. A further contrast to conventional systems: No vacuum pump is required. This significantly reduces the noise pollution for the user - making a major contribution to industrial health and safety.

The lap-grinder is easy to clean and it is possible to process up to 4 slides at the same time. Because the lap-grinder is equipped with a temperature-independent measurement controller, you always receive precise results - also with a fluctuating water temperature.

lap-grinder equipment

- Stainless steel housing/li>

- Touch panel

- Water controller

- Vacuum controller

- Storage space for 20 programs

technical data lap-grinder

cut-grinder primus

| Voltage | 230 V |

|---|---|

| Frequency | 50 Hz |

| Control voltage | 24V |

| Current draw | max 5A operation 3A |

| Weight | 135 kg |

Accessories

- Adhesion films

- Grinding paper 300 mm or 400 mm

in grains K 320, K 500, K 800, K 1000, K1200, K2500, K4000 - Care solution

- Slide 25 x 75 x 2 mm &

50 x 100 x 2 mm (we are happy to deliver other sizes on request) - Masks for the respective slides

- tainless steel care product

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"

Quality assurance

Mobile exhaust systems

Our mobile exhaust systems are the ideal assistant - and not just in the lab. Due to their compact design, our devices can be stored and moved around with ease. Meaning that a single device can be operated at multiple work stations.

The systems are suitable for the reliable and rapid removal of

- Solvent and adhesive fumes

- Formalin, acetone

- Grinding and polishing dust

- Soldering and laser smoke

and therefore make a significant contribution to maintaining health in your workplace. Through the wide range of optional

accessories, we can configure the ideal exhaust system for your requirements - for example for the targeted extraction of

adhesive fumes with the GL range.

We look forward to your inquiry.

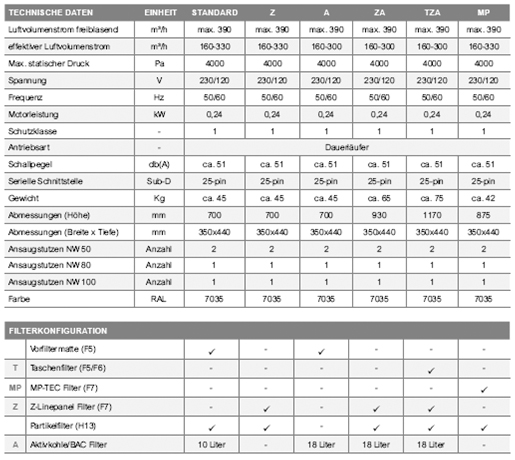

Example: technical data Mobile exhaust systems standard Z A ZA TZA MP (german)

back to top | Orders

Download catalog "world of polishing"

Download catalog "world of patho"