Diamond polishing agents: flawless results.

We have always placed great value on the top quality of the polishing and lapping agents that we develop and produce. We therefore use diamonds of natural and synthetic origins as active grinding components: The resilience of these precious stones - the hardest natural grinding substance to occur in nature - lends our products their unique characteristics.

Thanks to our constant quality controls through laser diffraction and image analysis, modern production techniques and over 30 years of specialist expertise, we are able to guarantee flawless and consistently reproducible application results. It is also due to this experience that we are able to find the ideal and therefore also the most economical solution for you. »dia-plus« is therefore not simply the name of a product group; it also stands for our performance promise: Diamonds plus know-how.

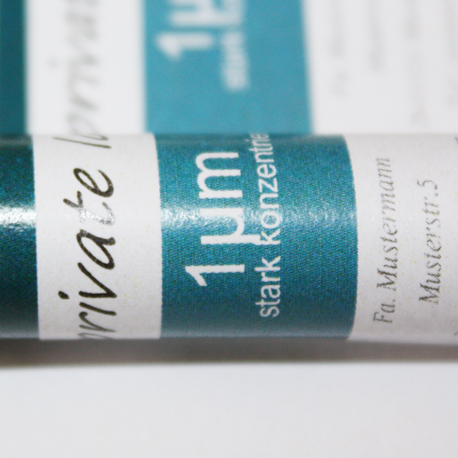

You can identify our products - the constituents of which are selected with consideration to the "Reach" regulations and are free of silicone - with ease due to the trade name:

| dia-plus | Diamond pastes with natural and synthetic diamonds in micro grain sizes |

|---|---|

| liqui-plus | Diamond suspensions and diamond emulsions |

What can we do for you?

You wish to find out more about our first-class products?

Simply get in touch with us: We look forward to hearing from you and will be happy to advise you!

Telephone +49 40 714873-0